Categories

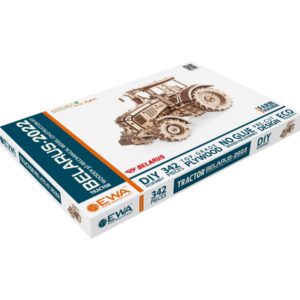

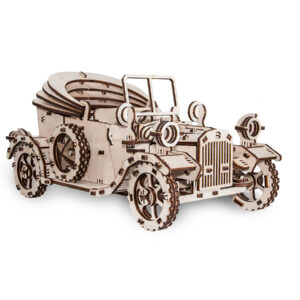

ECO Friendly

All pieces are made of natural wood. In harmony with nature.

Without Cola

Assemble hundreds of pieces without a single drop of glue.

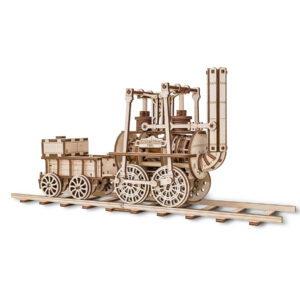

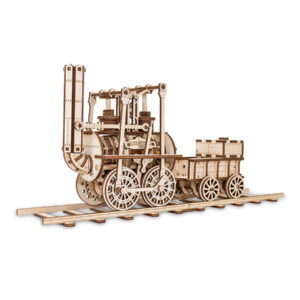

3D wooden models

Absolutely mechanical. Models come to life without batteries.